Shock Testing

Jump To:

Features

Literature

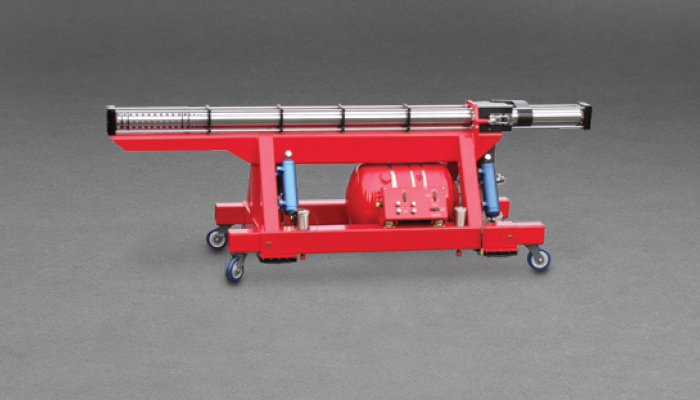

We provide end-to-end shock testing services complete with NIST traceable calibrated instrumentation and data reporting. Methods are consistent with MIL specification 810G. Preparations for the test day require only a contract, advance schedule planning, and the following technical information:

- Mounting pattern for test article

- Dimensions and approximate weight of test article

- Vibration levels needed in each direction to test

The shock test system is also used for a variety of other tasks including shock transmission testing on isolators and damping material research. Moog regularly tests shock isolators to both prove their durability and demonstrate isolation performance at high levels.

Shock testing Capabilities

- Pneumatic cannons that can provide shock levels in excess of 100 kGs

- Gantry with 1 Ton lifting capabilities

- Spectral Dynamics High-Speed Acquisition System, 5.0 MHz sampling rate on each channel

- Alias rejection > 95 dB below 1.25 MHz (analog filter included)

- Matlab based processing using ISO standard SRS code

- Acceleration levels up to 200 kGs