Moog CSA Engineering

Moog CSA Engineering is a recognized world leader in the field of vibration suppression, providing unparalleled experience in the analysis, design and production of a wide array of leading edge, high precision systems. We have the experience, capabilities, and creativity to find a solution to your most difficult problem, allowing you to focus on other core functions. By applying innovative engineering, combined with established methods and processes, we have the ability to give you successful results to your system or application.

Moog CSA delivers innovative products to control motion precisely and develop systems that combine vibration and motion control for aerospace and commercial applications. In addition, we support customers in energy, semiconductor manufacturing, medical and other markets. We have a history of over 25 years of meeting customer needs in government programs and commercial products, specializing in aerospace vehicles, structures and components.

Our Unique Capabilities

- Shock, Vibration and Other Products

- Engineering Analysis

- Design

- Precision Motion Products

- Systems Integration

- Vibration Testing

Shock, Vibration & Other Products

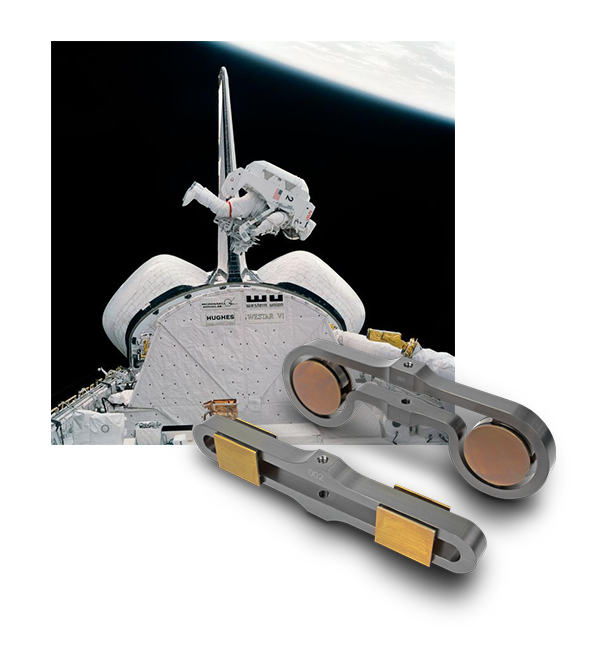

Moog CSA sells complete design services to solve shock and vibration conditions. We provide designed solutions for needs ranging from clean systems in space applications to industrial machinery on offshore platforms. Our background with attenuation methods and systems design generates simple and effective solutions. Our experience is unparalleled in both active and passive attenuation.

Shock and Vibration Isolation

Moog CSA regularly isolates spacecraft from launch vehicles. We design from heritage systems and use novel methods where appropriate. Simulations identify environments experienced by sensitive components and stresses on isolators early in the design process, avoiding iterations in hardware, and addressing design challenges quickly. Verification tests can often reduce uncertainties before the bulk of hardware is manufactured. Exceptionally clean materials and processes protect optics and other contamination-vulnerable hardware. AS 9100 certification assures that design and fabrication methods meet standards required for flight critical systems.

Vibration Damper

Some applications benefit most from a vibration damper alone. The scope of our abilities in vibration damping offers customers the widest practical selection of solutions.

Examples of dampers designed by Moog CSA are:

- Solar array mounts to the Hubble Space Telescope

- Tuned mass absorbers for thrust oscillation on Ares 1 vehicle

- Particle damper

- Cryogenic temperature dampers

- Viscoelastic elements

- Viscous oil dampers

We can perform predictions to indicate performance improvements offered by each solution above.

Engineering Analysis

All of our vibration isolation products have been designed through rigorous system simulation and component analysis which is a critical part of our design process. To ensure feasibility, our engineers look at a project from all perspectives necessary, with a focus on satisfying customer requirements.

Software

Once the component requirements are established, Moog CSA has the ability to rapidly iterate our mechanical designs with SolidWorks® three dimensional modeling and Simulation software. Once this stage is complete, we verify these initial analyses using the dedicated and industry respected finite element code, Nastran®. We have also developed our own internal codes for processing launch vehicle coupled loads analyses, and we have developed many Matlab® Simulink models for real-time active control system development.

System Level Analyses

When the finite element models of our completed designs are complete, we are then able to incorporate math model representations of these designs back into the system models. This is an iterative process which can provide valuable feedback for areas of improvement in the design. Our system level analyses consist of time-domain, frequency-response, random vibration, and stress analysis. Because some of our isolation and damper designs consist of viscoelastic or magnetic materials, we can implement non-linear material properties in our analyses.

Design

The design team at Moog CSA is recognized for excellence in providing highly engineered products and services in vibration control, motion control, and dynamically optimized structures. We have a proven ability to prevent failures, enhance reliability, and improve performance in your application. Additionally, we dynamically optimize structures that enable, complement, or support vibration and motion solutions. Our engineers have the agility and responsiveness in order to support your product development needs.

Integration between Design and Analysis

Tight integration between design and analysis allows us to produce lightweight parts designed for both strength and stiffness with confidence in performance whether the objective is vibration control, precision motion, or a test. Our finite element analysts work closely with mechanical design engineers to craft devices and components that meet requirements in creative and innovative ways.

Manufacturing

In-house manufacturing and integration at Moog CSA is supported by an established network of fabrication companies. We have longstanding relationships with several machine shops that are capable of producing parts to the quality we demand. Our engineers work closely with these suppliers to design parts compatible with machine tool capabilities. Because we work with smaller shops, we can support quick turnaround and rapid prototyping.

Hardware Development

Moog CSA develops hardware for space flight and other critical applications, and we have a quality control system in place to ensure that design, analysis, manufacturing and handling are consistent with customer requirements. We are experienced in the design of aerospace components using a variety of metals, elastomers, and other materials.

Unique Experience

At Moog CSA, mechanical design often overlaps with related disciplines. We design actuator components that incorporate electromagnetic, pneumatic and hydraulic elements. We also select materials and design details to optimize thermal properties and provide precise structures for hot or cold environments. Finally, design of vibration damping and isolation components requires another set of skills for high performance assemblies that combine stiff and compliant materials. We have unique experience in all of these areas.

Precision Motion Products

Precision motion applications, which include vibration isolation, motion simulation and payload position control, are exceedingly diverse and cannot be solved with a one-size-fits-all approach. Moog CSA can meet your wide range of design requirements from standard to high performance solutions. Our experienced engineering staff can design cost-effective products to meet your performance goals.

Our commitment to our customers does not end when the product ships out the door. We continue to provide services including on-site installation and training, test support, troubleshooting, and product upgrades. We pride ourselves on developing long term partnerships with customers who continually rely on Moog CSA when precision motion applications arise.

Flexibility is Our Specialty

Do you need a precision motion product for use inside a vacuum chamber? Does your application involve a cryogenic environment? Whether your payload is 1kg or 1000kg, our engineers have the flexibility and expertise to handle all types of unique requirements.

We build upon years of experience with custom applications to deliver exactly what our customers need. We also design custom graphical user interfaces to make our products even easier to use.

Solutions for Nearly Any Precision Motion Challenge

Whether the application calls for accurate pointing, high-speed motion simulation, or vibration isolation, Moog CSA has standard and custom solutions to meet your requirements. Learn more about the following precision motion products:

- Precision pointing hexapods for optics and cameras

- Motion simulation hexapods for high speed trajectory tracking

- Vibration isolation hexapods for small and large payloads

- Vibration isolation and motion control octopods for rectangular payloads and high-g loads

- Airborne stabilization / vibration isolation system for optical or electro-optical systems

- Jitter reduction for optical mounts

Systems Integration

We at Moog CSA focus on understanding all aspects of a systems integration challenge by taking a very detail-oriented approach. We rely on these strengths in implementing any of our vibration isolation, precision motion or SoftRide systems. Some examples include:

- Mechanical, electrical and magnetic modeling

- Dynamic and control system simulation

- Total quality approach to design, procurement, assembly, testing and delivery

We Rely on Expertise and Experience

We save our customers time and money by using a fast-paced but thorough approach to providing systems integration solutions. We offer unmatched experience in actuator selection, sensor selection, power electronics, material selection, system testing and more.

We believe in maintaining a very intimate approach, so our customers will always interact with the engineers directly. Some of our past projects include:

- Active vibration reduction of a launch vehicle

- Six degree of freedom electro-pneumatic vibration isolation system

- Six degree of freedom high speed motion simulators

- Piezoelectric hydraulic pump for UAV flight control surface actuation

- Motion simulation system for spacecraft components

By using our standard processes and tools for developing designs and/or systems matched to particular requirements, Moog CSA applies the appropriate technology for your program.

Vibration Testing

Moog CSA provides test services to diagnose the cause of high vibration levels in machinery and precision devices. Vibration can downgrade system performance or cause catastrophic failure. A well-designed test program in conjunction with our design and analysis engineering expertise provides high performance solutions to even the most challenging vibration problems.

We offer a complete package in our vibration test services: test fixture design, test planning development, highly trained test engineers and test equipment. Moog CSA can perform tests in the field or in our laboratories to characterize component performance or diagnostic experiments. Our engineering staff has years of experience in signal processing and will properly interpret measurements that feed into structural modification designs to solve your vibration problem.

Often measurements must be made at our customer’s facility to characterize the vibration environment and identify noise sources or troublesome structural dynamics. We use established test techniques for rotating equipment to identify the cause of the vibration, which is an important step toward implementing an effective structural modification.

Moog CSA has extensive capabilities to characterize components and full systems in our laboratories. Our wide range of instrumentation and actuators can be leveraged to solve your vibration problem with force capacities spanning from ounces to tons.

Specialized test methods we use in the field and laboratory include the following:

- Direct complex stiffness tests to characterize stiffness and loss of materials or structures at controlled temperatures

- Run-up/spin-down with Campbell diagram and spectral waterfall map analyses

- Force state mapping for nonlinear test articles

- Time history-based tests for nonlinear structures

Modal Testing

Our years of experience in the modal testing field complement operating measurement techniques. An experimental modal analysis provides estimates of natural frequencies, damping ratios and mode shapes. We use shakers, impact hammers or step relaxation excitation methods based on the test article communicated from a computer hard disk flexure to an aircraft.

Our highly trained testing engineering staff can use portable data acquisition systems for small tests in your facility or our large channel count modal systems for tests that require hundreds of response measurements. Test and analysis techniques can utilize multiple shakers to reduce test time and excite all of the test article resonances simultaneously.

We employ the following approaches when planning for and executing modal tests:

- Pseudo mass cross orthogonality checks for exciter and response sensor location and direction selection as a pre-test analysis

- Model-to-test orthogonality checks for test/model correlation

- Modal assurance criteria checks between model and test mode shapes and test-to-test mode shape checks

- Polar plot analyses of estimated mode shapes

Experimental modal analysis results are instrumental in tuning models. Finite element model development and tuning is one of our core capabilities- it is the foundation for designing and implementing an effective vibration mitigation approach.

Product and Service Offerings

Moog CSA Engineering offers established products and services that are appropriate to a variety of applications. When customers have specialized needs that cannot be met exactly by our existing products or other available technology, we engineer custom versions and tailor new products to meet application-specific requirements for vibration suppression, vibration isolation and motion control.

About Moog CSA Engineering

CSA Engineering was founded in November 1982 by three Ph.D. engineers who had been colleagues at a San Francisco Bay Area materials and engineering firm. Conor Johnson, Warren Gibson, and David Kienholz wanted to start a company where they could develop and apply their expertise in structural dynamics and related fields. They organized the new company around certain core values.

Currently, as a wholly-owned subsidiary of Moog, Inc. that operates as the Vibration Control Business Unit in the Space and Defense Group, our reputation is our most valuable asset. Long-term customer relationships are emphasized and short-term gains de-emphasized. Moog CSA seeks to be recognized for superior engineering capabilities, flexible response to customer requirements and the ability to tackle difficult multi-disciplinary challenges.